This Waste Management Plan (WMP) sets out in

detail the approaches CRBC �V KADEN JV should adopt in the management of waste

generated from the various different construction activities. It also sets out the

procedures for the waste management activities and requirements during the

construction.

To demonstrate the

Project Team��s commitment on the continual improvement of our waste management

performance, the project waste management policy has been established as below:

The following

legislation relates to the handling, treatment and disposal of wastes in Hong

Kong, and should be observed with regard to all wastes generated and requiring

disposal due to the construction, where applicable:

�P

Waste Disposal Ordinance (Cap 354)

�P

Waste Disposal (Chemical Waste)

(General) Regulation (Cap 354)

�P

Waste Disposal (Charges for Disposal of

Construction Waste) Regulation (Cap 354)

�P

Land (Miscellaneous Provisions)

Ordinance (Cap 28)

�P

Public health and Municipal Services

Ordinance (Cap 132) �V Public Cleansing and Prevention of Nuisances (Urban

Council) and (Regional Council) By-Laws

The Waste Disposal

Ordinance (WDO) prohibits the unauthorized disposal of wastes. The illegal tipping or flytipping

of wastes on unauthorized sites is also controlled under the WDO. Under the

Waste Disposal (Construction Waste Disposal Charging Scheme) Regulation,

project team should apply for a billing account from EPD for disposal of

construction wastes generated from the project. The regulation prescribes the

requirements of handling of construction wastes on site and the construction

waste disposal-charging scheme.

Under the Waste

Disposal (Chemical Waste) (General) Regulation all producers of chemical wastes

(including asbestos) must register with EPD and treat their wastes either

utilizing on-site plant licensed by EPD, or arranging for a licensed collector

to take the wastes to a licensed facility. The regulation also prescribes the

storage facilities to be provided on site, including labeling warning signs,

and requires the preparation of written procedures and training to deal with

emergencies such as spillages, leakages or accidents arising from the storage

of chemical wastes.

Construction wastes that are wholly inert would be taken to public

dumps. Public dumps usually form part of land reclamation schemes operated by

the Civil Engineering and Development Department (CEDD). The Land

(Miscellaneous Provisions) Ordinance requires that individuals or companies who

deliver suitable construction wastes to public dumps obtain dumping licenses.

CEDD issues the licenses under delegated powers from the Director of Lands.

The Public Cleansing and Prevention of Nuisances By-Laws provide

further controls on the illegal tipping of wastes on unauthorized (unlicensed)

sites.

The project team should obtain all necessary permits and licenses under

these ordinances including, but not limited to:

�P

Chemical waste permits/ licenses under

the Waste Disposal Ordinance (Cap 354)

�P

Billing Account for construction waste

disposal-charging scheme (Cap 354)

The following

guidelines related to waste management and disposal would be adhered to during construction

of the project:

�P

Waste Disposal Plan for Hong Kong

(1989), Planning, Environmental and Lands Branch, Hong Kong Government

Secretarial

�P

Environmental Guidelines for Planning

in Hong Kong. Hong Kong Planning Standards and Guidelines (1990)

�P

New Disposal Arrangements for

Construction Waste. EPD and CED (1992)

�P

Code of Practice on the Packaging,

Labeling and Storage of Chemical Wastes (2002), Environmental Protection

Department

�P

Code of Practice on the Handling

Transportation and Disposal of Asbestos Waste, Environmental Protection

Department

�P

Code of Practice on the Handling,

Transportation and Disposal of Asbestos Waste

�P

Code of Practice for Demolition of

Buildings 2004

�P

Works Branch Technical Circular No.

12/00, Fill Management

�P

Works Branch Technical Circular No.

32/92, The Use of Tropical Hard Wood on Construction Site

�P

Works Branch Technical Circular No.

2/93, Public Dumps

�P

Works Branch Technical Circular No.

16/96, Wet Soil in Public Dumps

�P

Works Bureau Technical Circular No.

4/98, Use of Public Fill in Reclamation & Earth Filling Projects

�P

Works Branch Technical Circular No.

5/98, On-site Sorting of Construction Waste on Demolition Site

�P

Works Branch Technical Circular No.

29/00, Waste Management Plan

�P

Works Branch Technical Circular No.

25/99, 25/99A and 25/99 Incorporation of Information on Construction and

Demolition Material Management in Public Works Sub-committee Papers

�P

Environmental, Transport and Works

Branch Technical Circular No. 33/02, Management of Construction and Demolition Material

Including Rocks

�P

Works Branch Technical Circular No.

6/02 and 6/02A, Enhanced Specification for Site Cleanliness and Tidiness

�P

Works Bureau Technical Circular No.

31/04 Trip Ticket System for Disposal of Construction & Demolition

Materials

�P

Works Bureau Technical Circular No.

15/03, Waste Management on Construction Sites

�P

Works Bureau Technical Circular No.

22/03, Additional Measures to Improve Site Cleanliness and Control Mosquito

Breeding on Construction Site

�P

Waste Reduction Framework Plan, 1998 to

2007, Planning, Environmental and Lands Bureau, Government Secretariat, 5

November 1998

�P

A Guide to the Registration of Chemical

Waste Producers

�P

A Guide to the Chemical Waste Control

Scheme

�P

Practice Notes for Authorized Persons

and Registered Structural Engineers (PNAP) 71

�P

Code of Practice: Safety and Health at

Work with Asbestos

�P

Code of Practice: Control of Asbestos

at Work

�P

Code of Practice for Demolition of

Building 2004

�P

Code of Practice on the Handling,

Transport and Disposal of Asbestos Waste

�P

Factories and Industrial Undertakings

(Asbestos) (Approval of Respiratory Protective Equipment) Notice

�P

Air Pollution Control Ordinance

�P

The Protection of Workers�� Health

Series �V Asbestos

�P

Construction Sites (Safety) Regulations

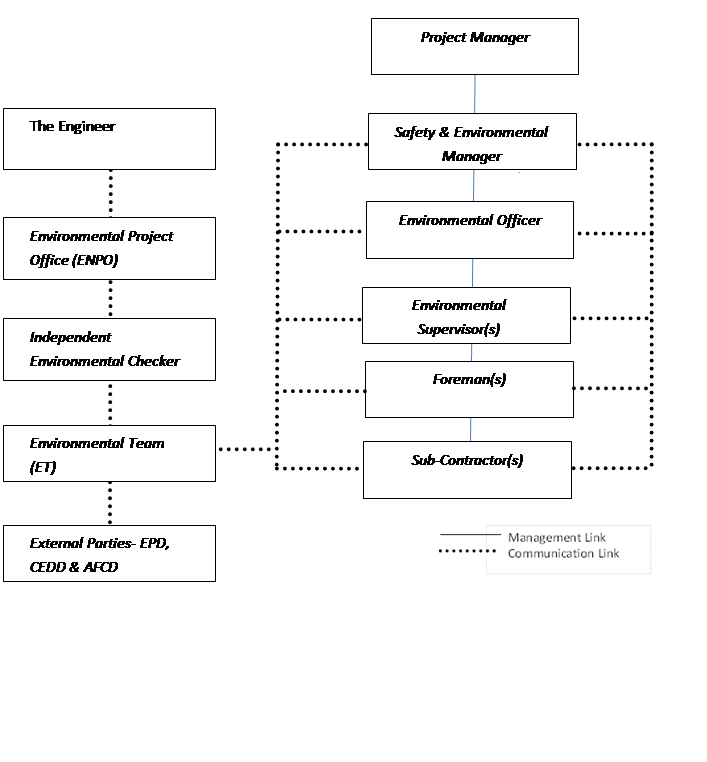

Appendix A of this WMP contains

a Project Organization Chart showing the reporting channels and functional

relationships of the various personnel currently employed and to be employed in

the future on this project.

All personnel of contractor team are required to implement waste management and

measures within their work area. A summary of the responsibilities of key

personnel:

The Engineer

The Engineer is responsible for overseeing

the construction works and for ensuring that the works are undertaken by the

Contractor in accordance with the specification and contractual requirements.

The duties and responsibilities of the Engineer with respect to EM&A may

include:

�P

Supervise the Contractor��s activities

and ensure that the requirements in relevant regulation and terms are fully

complied with.

�P

Inform the Contractor when action is

required to reduce environmental impacts in accordance with the Event and

Action Plans;

�P

Participate in joint site inspections

and audits; and

�P

Adhere to the procedures for carrying

out complaint investigations.

Environmental Project Office

The independent Environmental Project Office

(ENPO) is set up by the Client. The purpose of the ENPO is to oversee the

cumulative environmental impacts arising from this Contract and other

concurrent projects in the adjoining area and to liaise closely with the

mainland project teams for the HZMB Main Bridge.

Contractor

The Contractor (JV) shall:

�P

Ensure compliance with the procedures

and recommendations set out in this WMP;

�P

Work within the scope of the

construction contract and other tender documents;

�P

Participate in the site inspections

undertaken by the Environmental Team as required and undertake any corrective

actions instructed by the Engineer; and

�P

Take responsibility and strictly adhere

to the guidelines of the EM&A programme and

complementary protocols developed by their staffs.

The key personnel for environmental

matters include the Project Manager, Environmental Team Leader, Environmental

Officer and Environmental Supervisor.

Their responsibilities are listed below:

Project Manager

He is the Management Representative of the JV. His overall

responsibilities on environmental issues of the Project include:

�P Oversee the implementation of the WMP; and

�P Assign adequate resources for the implementation of the WMP.

Site Agent

His/ Her responsibilities include:

�P

Supervise & co-ordinate project

team and sub-contractors for construction works to meet the quality, safety

& environmental and schedule requirements

�P

Implement and adherence to statutory

environmental requirement

�P

Ensure design, work methods and

practices take due consideration of environmental requirements

�P

Release / accept work which complies

with contract / specification requirements

�P

Ensure that all project personnel are

adequately trained and experienced

�P

Ensure all necessary statutory permits

and license being applied

�P

Ensure all environmental mitigation

equipment and installations are well maintained

�P

Ensure the recommendations and

instruction from Engineer and Environmental Officer are implemented to improve

the environmental practice and carry out immediate action to rectify the

non-compliance of environmental requirements

�P

In the event of unwillingness of site

workers (including sub-contractors) to follow correct procedures, carry out

necessary actions to rectify the situation. Necessary actions include but not limited to administrative

charges, issue warning letter, expel from site and immediate termination of the

sub-contract.

�P

Carry out monthly environmental

management performance review with project team and review the overall

environmental performance on a quarterly basis. Report environmental

performance in Project Monthly Review Report

�P

Report any warning / advises received

from Government Authorities (e.g. EPD or Labour

Department)

�P

Maintain relevant environmental records

Environmental Team (ET) Leader

The leader of the Environmental Team shall be an independent party from

the Contractor and have relevant professional qualifications, or have

sufficient relevant EM&A experience subject to approval of the Engineer and

the EPD. The duties

of ETL are:

�P

Identify the

potential hazardous waste whenever possible and take proactive actions before

problems arise

�P

Provide

briefing to the contractor��s project team as necessary on the waste management

requirements.

Environmental Team (ET)

The ET Leader and the ET shall be employed to conduct the EM&A programme and ensure the Contractor��s compliance with the

project��s environmental performance requirements during the Contract. The

duties are:

�P

Environmental site surveillance;

�P

Audit of compliance with environmental

protection, and pollution prevention and control regulations;

�P

Monitor the implementation of

environmental mitigation measures;

�P

Monitor compliance with the

environmental protection clauses/specifications in the Contract;

�P

Adhere to the procedures for carrying

out complaint investigation, evaluation and identification of corrective

measures;

�P

Liaison with Independent Checker

(Environment) on all environmental performance matters, and timely submission

of all relevant EM&A preform for IEC��s approval;

�P

Advice to the Contractor on

environmental improvement, awareness, enhancement matters, etc., on site;

�P

Timely submission of the EM&A

report to the Project Proponent and the Director of Environmental Protection.

�P

Regularly

check the waste chit record to ensure the procedure observing the relative

environmental regulations.

�P

Ensure the

Contractor has implemented the mitigation measures as stated in the EM&A

Manual.

Environmental Officer

An Environmental

Officer will be present full time on site for inspection, supervision and

monitoring of the environmental performance, including waste management of the Contract. The duties of Environmental Officer in

the area of waste management will include:

�P

Assist the Q&E Manager in

preparation, implement and update the Waste Management Plan;

�P

Carry out inspections of the Site and

attend the weekly environmental walk for checking and identifying any waste

management practice on site not complying with this Plan and/ or relevant

environmental regulations in Hong Kong;

�P

Assist the Q&E Manager on the

implementation of site practice to meet the requirement on waste avoidance or

waste reduction;

�P

Advise the Q&E Manager on the

opportunities for reuse/ recycling of C&D materials generated on site;

�P

Properly keep the records of the waste

reuse, recycle or disposal for inspection by the Engineer;

�P

Maintain a database to trace the C&D

materials and waste to be generated from the project;

�P

Report and rectify any environmental

mal-practice on site to avoid the generation of unnecessary C&D materials

or waste from the project;

�P

Carry out training to the JV staff to

promote the environmental awareness.

Environmental Supervisor(s)

The Environmental Supervisor is an assistant to the EO in environmental

matters. He shall assist the EO in

his day-to-day management of on-site environmental issues and act on behalf of

the EO during his absence.

Site Engineer(s)/ Foreman(s)

The Site Engineers

/ Foremen appointed by the JV are responsible for the following duties in

relation to environmental control:

�P

Assist the project management team to implement

in the Contract all environmental related plans, including but not limit to

Environmental Management Plan, Waste Management Plan, Spoil Disposal Plan and

etc.;

�P

Control the Contract to fulfill the

requirement of waste management as detailed in this Plan;

�P

Ensure the disposal of C&D

materials and waste was directed to designated areas as approved by The

Engineer;

�P

Report to the Environmental Officer on

the non-compliance of the frontline operatives or the sub-contractors on

handling of the C&D materials and the waste as according to this Plan;

�P

Implement remedial actions or

mitigation measures on the non-compliance regarding the waste management on

site;

�P

Conduct environmental tool box talks to

the labourers and workers to make them aware of

environmental practice;

�P

Collaborate with the Environmental

Officer in the implementation of waste management measures;

�P

Assist the Environmental Officer in

arranging the necessary workforce for carrying out corrective actions.

Sub-contractor

All subcontractors

and other employees have the duty to carry out agreed waste management

practices as instructed by the Contract management. Every employee will report promptly to

project management any non-compliance of environmental protection and

mitigation measures. They will

actively participate in and co-operate with the Contract management to achieve

the environmental objectives.

Effective 2-way

communications will be developed to initiate the flow of environmental

information among different parties. The communication is mainly achieved

through the environmental correspondence, environmental report, SSEMC &

SSEC meeting, environmental briefing and training, site inspection, etc. and

environmental awareness promotion activities between the JV and site works and

sub-contractors.

Table 3.1 -

Means of Communications on Environmental Issues

|

Means

|

Frequency

|

Purpose/Action

|

Responsible Party

|

|

Environmental correspondence

|

As required

|

Written

communication among the ET, JV and the Engineer

|

ET, JV and Engineer Representative

|

|

Monthly Environmental report

|

Monthly

|

Report on

monitoring and audit results for the Project

|

EO

|

|

Notice of

exceedance, non-compliance, complaint

|

As required

|

Written notification

to different members of the JV requesting appropriate actions

|

JV, ET, Engineer Representative. Action according to procedures given in Sections 7.0.

|

|

licenses and

permits

|

As required

|

On receipt of a license

or permit, the original shall be kept at the site office and a copy shall be

sent to AECOM

|

EO

|

|

SSEMC & SSEC

meeting

|

Monthly

|

Face-to-face

communications between the ET and other disciplines

|

ET Leader, EO,

ES, Sub-contractors, Worker��s Representative

|

|

Weekly

Environmental Walk

|

Weekly

|

Face-to-face

communications between the EO and the ET Leader during the site inspection

|

EO, ES, Engineer

|

|

Induction

training

|

Contractual

requirement for new workers and sub-contractors

|

Promote awareness

of environmental procedures among workers and sub-contractors

|

EO, ES

|

|

Tool Box Talk

|

Contractual

requirement

|

Promote on-going

awareness of environmental procedures among workers and sub-contractors

|

EO, ES

|

|

Site inspection

|

Continually

|

Promote

awareness of environmental procedures among workers and sub-contractors via

routine and specific talks

|

ET Leader, EO,

ES

|

|

Environmental

records (i.e. Monthly Summary of WFT and Summary table on the use of timber)

|

Continually

|

Records of

training, permits, communications, etc., refer to Section 6

|

EO, to be kept

at site office

|

Note:

1. The follow-up actions on environmental issues in the SSEMC meetings and

SSEC meetings will be carried out ASAP and reported in the forthcoming meetings.

.The EO/ES shall monitor the progress of the follow-up actions.

2. The environmental records such as permits and licenses will be checked

by EO regularly to ensure that those records are valid and comply with the

ordinances.

Construction and Demolition (C&D) materials include public fill

(inert material) and C&D wastes (non-inert material). Public fill should

comprise broken concrete, brick and aggregates, etc. C&D wastes should

comprise unwanted materials generated during construction, including rejected

structures and materials, materials which have been over ordered or are surplus

to requirement and materials, which have been used and discarded.

The following

types of waste would be generated from the construction activities:

�P

Excavated material

�P

C&D material containing inert and non-inert materials

�P

Chemical waste

�P

General refuse

�P

Sewage

The disposal sites

for the wastes generated from the project as shown in the following table.

Table 4.1 -

Sources and Waste and Corresponding Disposal Site

|

Waste Type

|

Examples

|

Disposal Site

|

Estimate Volume

Generated

|

Estimate Volume Reused on/off-site

|

Estimate Volume Disposed off-site

|

|

Excavated material

|

�P

Rock

�P

Rubble

�P

Boulder

�P

Soil

�P

Sand

|

�P

Tuen Mun Area 38 Fill Bank�V for inert construction waste excluding slurry and bentonite;

�P

Tseung

Kwan O Area 137 Fill Bank �V for slurry and bentonite

|

452660 m3

|

112490 m3

|

340170 m3

|

|

C&D material �V public fill (inert)

|

�P

Broken concrete

�P

Brick

�P

Aggregate

�P

Asphalt

�P

Tile

�P

Masonry

�P

Used bentonite

|

3000 m3

|

1000 m3

|

2000 m3

|

|

C&D material �V C&D waste (non-inert)

|

�P

Wood

�P

Bamboo

�P

Plastic

|

�P

West New Territories (WENT) Landfill or other disposal outlets as

approved by the Engineer Representative

|

4800 m3

|

400 m3

|

4400 m3

|

|

Chemical waste

|

�P

Used oil

�P

Spent solvent

|

�P

Chemical Waste Treatment Facility at Tsing Yi

�P

Other approved facility

|

30 m3

|

N/A

|

30 m3

|

|

Chemical waste

(Asbestos)

|

�P

Asbestos Cement pipe

|

�P

Landfill or other disposal outlets as approved by the Engineer

|

0

|

N/A

|

0

|

|

General Refuse

|

�P

Packaging waste

�P

Office waste

|

�P

West New Territories (WENT) Landfill or other disposal outlets as

approved by the Engineer

|

2400 m3

|

N/A

|

2400 m3

|

|

Sewage

|

�P

Chemical toilet

�P

Site office toilet

|

�P

Licensed contractor

�P

Discharge to existing sewer

|

30 m3/d

20 m3/d

|

N/A

|

30 m3/d

20 m3/d

|

In order to make use of

C&D materials generated by the Site, JV will identify and use recycling

facilities or other construction sites where such materials can be used before

obtaining the written approval of the Engineer. Relevant information should be

submitted to the Engineer as following:

(a)

A detailed

description of the alternative disposal ground, including location, lot number

(where appropriate), location plan and photographs of the proposed alternative

disposal grounds showing the surrounding environment and land use;

(b)

where the

alternative disposal ground is a private construction site, a letter from each

of the relevant authorities, such as Agriculture, Fisheries and Conservation

Department, Lands Department and Planning Department, to comment on suitability

of the site under their respective purview, and a letter from the Authorized

Person of the development to confirm:-

1)

The C&D

materials for use in the development is acceptable;

2)

The

land/pond filling in the proposed alternative disposal ground and the use of

land so formed by the C&D materials are in conformity with the statutory

town plan/lease condition; and

3)

The

Engineer��s staffs are allowed to enter the alternative ground to conduct

inspections where necessary.

(c)

where the

alternative disposal is a private recycling facility, it is on the recyclers��

list for C&D materials recognized by EPD, as well as a letter from the

operator to confirm the Engineer��s staff are allowed to enter the recycling

facility to conduct inspections where necessary;

(d)

where the

alternative disposal ground is a construction site of Government (other than a

government contract quarry), Hong Kong Housing Authority or Mass Transit

Railway Corporation, a written consent from the project office of the alternative

disposal ground to use the C&D materials generated from the Site;

(e)

where the

alternative disposal ground is a government contract quarry, a written consent

from the Mines Division of Civil Engineering and Development Department to

import the C&D materials generated from the Site;

(f)

the

estimated quantity and type of C&D materials to be used/processed in the

alternative disposal ground and the approximate delivery programme,

together with the name, post and specimen signature of the competent person to

sign the Disposal Delivery Form (DDF); and

(g)

a system for transmitting disposal records

from the alternative disposal ground to the Engineer��s Representative.

The purpose of this section is to describe the proposed mitigation

measures considered to ensure that all wastes generated during the construction

and demolition are well-managed on-site, transported and disposed of in a

manner that is both environmentally acceptable and in full compliance with

statutory and contractual requirements. A Site Layout Plan indicated the area

for the waste management such as temporary storage area, waste sorting area and

disposal area as presented in Appendix B.

�� Design and programme excavation works so that

the materials excavated can be re-used as back-fill material to balance cut and

fill and hence reduce the generation of excavated materials.

�� Right amount of raw materials should be ordered at the right time with

proper control and documentation on material flow to minimize over-ordering.

Raw materials should be fully utilized to avoid wastage

�� Surplus materials should be returned to stock in centralized area with

suitable protective measures. If possible, surplus materials should be exchange

with other sites, to minimize material wastage

�� Careful design and planning and good site management should be

maintained to minimize over ordering and generation of waste materials such as

concrete, mortars and cement grouts

�� Sequence of

demolition should be planned to allow the separation and sorting of building

materials.

�� Avoid, reduce or minimize the use of timber in temporary works

construction as far

�� as possible. Procedures of using timber should be established guiding the

use of timber on site, in order to reduce or minimize the use of timber. The

design of formwork should maximize the use of standard wooden panels so that

high level of reuse can be achieved

�� Steel false work should be used as much as possible to reduce the

amount of waste timber generated from the project

�� Current operation procedures including any waste reduction measures

should be reviewed, especially during installation and cutting, to avoid

unnecessary use

�� Broken items or offcuts should be used when sections of small lengths

are required

�� If cut and fill could not be balanced on-site, suitable excavated

materials should be sorted on site to recover the inert portions (e.g. soil and

broken rock) for reuse on site before the remaining materials are disposed off site or disposal to designated Public Filling Facility

�� Carefully plan/program excavation and backfilling activities so that

excavated materials can be used for backfilling within the site

�� Excavated material should be reused as close to the point of excavation

and as soon after excavation as possible and directly transferred to the area

of deposition, if practicable.

�� The inert C&D materials generated from the toll plaza cut slopes will be used for construction of the raised platform for the toll plaza where

possible.

�� All C&D materials arising from or in connection with demolition

work should be sorted on-site and be separated into different groups for

disposal at landfills, public filling facilities or recycling appropriate

�� Identify and list out all work processes or activities that should

generate reusable/ recyclable materials during construction and demolition

�� For those suitable inert C&D materials (e.g. broken concrete from

demolition or road improvement works) should be properly sorted for recycling

into aggregates and recover the materials for on -site usage

�� Demolition debris from demolition works should be sorted to recover on

site broken concrete, reinforcement bars, mechanical and electrical fittings as

well as other building services fittings / materials that have established

recycling outlets

�� Procedures of the handling of reusable/ recyclable materials should be

established

�� Recycle suitable C&D materials by transporting the materials to

designated C&D materials recycling facilities for processing

�� All materials should be reused on site as far as practicable, including

formwork plywood, hoardings, scaffolding, trench supports, topsoil and

excavated materials.

�� Where necessary, alternatives such as metal scaffolding, steel formwork

or plastic facing should be considered to increase the potential for reuse.

�� Suitable materials, such as metal should be recovered on site for

collection by recycling contractors

�� All cardboard and paper packaging (for plant, equipment and materials)

should be recovered on site, properly stockpiled in dry condition and covered

to prevent cross contamination by other C&D materials

�� Reputable recycling contractors with valid licenses and fulfilling all

the legislative requirements should be employed to facilitate that recyclable

materials sorted from the site are collected with reasonable care

�� The quantities of all the recyclable materials should be recorded

before removal off site

The materials stockpiled on-site should

be managed in order to prevent any potential impacts. Following measures should

be considered in order to properly manage the stockpiled materials:

�� Identify and

provide sufficient space for temporary storage of C&D materials to

facilitate collection and/ or sorting on site

�� Stockpiled

materials should be sited away from any stream courses so as to avoid releasing

materials into the water bodies

�� Demolished debris

should not be accumulated on the floors unless the debris accumulation is

justified by engineering calculations

�� No stockpile of

construction materials, debris, formworks, or other forms of obstructions is

allowed to block the accesses throughout the entire construction period

�� Location to

minimize visual impacts and nuisance related to noise and air quality (dust) to

any sensitive receivers

�� Storage of

material on site should be kept to a minimum to avoid nuisance to local

residents

�� Keeping the movement

of stockpiled material to a minimum

��

�� Stockpiled

materials should be covered by tarpaulins and/or watered as appropriate to

prevent windblown dust and/or surface run-off.

�� Measures such as

providing sand bag barriers should be provided to prevent the washing away of

construction materials, soil, silt or debris into any drainage system. Any

washout of construction or excavated materials should be diverted to the

drainage system via sediment traps

�� All surplus

excavated material generated from the project should be disposed of at the

designated Public Filling Facility

�� According to the

Waste Disposal (Charges for Disposal of Construction Waste) Regulation (Cap.

354N), Construction Waste Disposal Charging Scheme mentioned in Section 5.10 in

this WMP should be implemented during the construction.

�� The acceptance

criteria for Public Filling Facility and Landfill should be followed

�� All inert C&D

materials generated from this contract should be disposed of at the designated Public

Filling Facility. Such materials should be free from marine mud, household

refuse, plastic, metal, industrial and chemical waste, animal and vegetable

matter and other matter considered unsuitable by Filling Supervisor

�� All dump trucks

used for delivery of public fill to public filling facilities should have valid

Dumping Licenses issued by CEDD. The inert C&D materials delivered to the

public filling facilities should be in accordance with the conditions in the

dumping license

�� All non-inert

portions of C&D material (C&D waste) generated from the project should

be disposed of at the designated landfill and/ or other disposal outlet as

directed by the Engineer. Should provide EPD with one week��s advance notice

before starting to deliver the C&D waste to the landfills and should inform

EPD of any subsequent changes to the disposal programme

during the contract period

�� Trees and

vegetation should be stripped prior to site clearance, chopped and compacted

using suitable mobile compactors to reduce the volume of material to be

transported and disposed of

�� Should not permit

any sewage, wastewater or effluent containing sand, cement, silt or any other

suspended or dissolved material to flow from the site onto any adjoining land

or allow any waste matter or refuse which is not part of the final product from

waste processing plants to be deposited anywhere within the site or onto any

adjoining land

�� In order to

minimize the impacts of demolition works, the wastes should be cleared as

quickly as possible after demolition

�� When any

components of a structure or water mains to be demolished and are suspected to

be consisting of asbestos, the project team should inform the ER. Any work which involves the use or handling of asbestos containing

materials must strictly follow the following procedure:

�� employ a

registered asbestos consultant to conduct an asbestos investigation and prepare

an asbestos investigation report and an asbestos abatement plan;

��

�� submit the

asbestos investigation report and the asbestos abatement plan to the

Environmental Protection Department at least 28 days before start work on the

asbestos containing materials;

��

�� notify the

Environmental Protection Department of the date of commencement of work on

asbestos containing materials at least 28 days in advance;

��

�� employ a

registered asbestos contractor to carry out the asbestos work in accordance

with the asbestos abatement plan;

��

�� employ a

registered asbestos consultant to supervise the implementation of the asbestos abatement

plan and the work of the registered asbestos contractor; and

�� employ a registered asbestos laboratory to conduct sampling and analysis for

the asbestos work.

�� Responsible for

good site practices, arrangements for collection and effective disposal to an

appropriate facility, of all wastes generated at the site

�� Training of site

personnel in proper waste management and chemical waste handling procedures

�� Provision of

sufficient waste disposal points and regular collection for disposal

�� Appropriate

measures to minimize windblown litter and dust during transportation of waste

by either covering trucks or by transporting wastes in enclosed containers

�� Regular cleaning

and maintenance programme for drainage systems, sumps

and oil interceptors

�� A recording system

for the amount of wastes generated, recycled and disposed of (including the

disposal sites).

A trip ticket system (TTS) for the removal of

construction and demolition (C&D) materials from the Site to the designated

disposal ground or alternative disposal ground will be implemented as according

to the Particular Specification.

The system will be developed and presented in the Waste Management Plan

to be prepared for the project.

JV willl inform the

Engineer of the account number of the billing account for disposal of

construction waste under the Waste Disposal (Designated Waste Disposal

Facility) Regulation (Cap. 354L). This is to enable the Engineer to check the

disposal records posted at the Environmental Protection Department��s website.

The Engineer will provide the account number to the Civil Engineering and

Development Department for overall monitoring of the trip ticket system,

detecting and taking action to deal with malpractice such as overloading of

dump trucks and improper covering of load, and compiling statistics as well as

counting eligible trips for mechanical dump truck covers under the pay for

safety and environment scheme / pay for safety scheme.

Site Management

Plan for Trip Ticket Implementation

A Site Management Plan (The Plan) will be prepared which includes the

implementation of TTS. The Plan should include site organization and staff

duties, disposal programme, site procedures for duly completed of CHIT/DDF, as

presented in Appendix E and Appendix F etc.

A comprehensive register of the disposal delivery for recording the

disposal of C&D materials and waste will be established. The register will

also cover the recyclable materials removed by the recycling contractors off

the Site. The quantity (ton) of the C&D material shall be recorded in the

register.

Record Keeping

For the management of CHIT/DDF, the following procedures and record keep

will be implemented to all dumping activities.

(a) For each truckload of C&D materials leaving

the Site, the truck driver must bear a duly completed CHIT/ DDF;

(b) A daily record of disposal, as presented in Appendix D, of C&D materials from

the Site including CHIT/ DDF numbers, vehicle registration marks, drivers��

particulars, approximate volume, C&D materials type, designated disposal

ground, departure time from the Site, actual disposal ground and arrival time

at disposal ground should be maintained. Part 1of the DRS completed by JV in

duplicate and inform the Engineer��s staff before departure of the vehicle. The

Engineer��s staff shall sign Part 1 of the DRS before departure of the trucks,

or to suit site operations at other time to be agreed between the Engineer��s

Representative and JV;

(c) The truck shall proceed to the disposal ground

as stipulated in the designated disposal ground. The truck driver shall present

the CHIT/ DDF to the operator of the disposal ground. For a prescribed

facility, if the C&D materials accord with the acceptance criteria, disposal

of the materials will be permitted and the facility operator will give the

driver a Transaction Record Slip and stamp the CHIT.

(d)

For

disposal ground other than prescribed facilities, the DDF should be signed off

by a competent person as agreed by the Engineer at the disposal ground to

confirm completion of each trip. A daily record with details of each disposal

trip from the Site to the disposal ground will be maintained. The completed

Part 2 of the DRS form should be submitted to the Engineer.

Chemical waste, as defined under the Waste

Disposal (Chemical Waste) (General) Regulation, includes any substance being

scrap material, or unwanted substances specified under Schedule 1 of the Regulation.

Substances likely to be generated by construction activities arise from the

maintenance of construction plant and equipment. These include, but not limited

to the following:

��

Scrap batteries or spent acid/alkali from their maintenance;

��

Used engine oils, hydraulic fluids and waste fuel;

��

Spent mineral oils/cleaning fluids from mechanical machinery; and

��

Spent solvents/solution, some of which may be halogenated, from

equipment cleaning activities.

It is anticipated that the quantity of chemical

waste, such as lubricating oil and solvent produced from plant maintenance,

should be small for this project.

Storage, handling, transport and disposal of chemical waste should be

arranged in accordance with the Code of Practice on the Packaging, Labeling and

Storage of Chemical Waste published by EPD.

General:

�� No maintenance

activities which may generate chemical wastes should be undertaken directly on

the ground;

�� Stored volume shall not be kept more than 450 litres

unless the specification has been approved by the EPD. Storage area should be

enclosed by three sides by a wall, partition of fence that is at least 2m

height or height of tallest container with adequate ventilation and space;

�� Any unused chemicals or those with remaining functional capacity shall

be recycled;

Containers used for the storage of chemical wastes:

�� Be suitable for the substance they are holding, resistant to corrosion,

maintained in a good condition, and securely closed

�� Have a capacity of less than 450 litre unless

the specifications have been approved by EPD

�� Display a label in English and Chinese in accordance with instructions

prescribed in Schedule 2 of the Regulation

Labeling:

��

Every container of chemical waste

should bear an appropriate label containing the particular details of the

chemical waste it contained. The waste producer should ensure that the

information contained on the label is accurate and sufficient so as to enable

proper and safe handling, storage and transport of the chemical waste

Storage area:

��

Be clearly labeled and used solely for

the storage of chemical waste

��

Be enclosed on at least 3 sides

��

Have an impermeable floor and bounding of

sufficient capacity to accommodate 110% of the volume of the largest container

or 20% of the total volume of waste stored in that area, whichever is the

greatest

��

Have adequate ventilation

��

Be covered to prevent rainfall entering

��

Be arranged so that incompatible

materials are adequately separated

Disposal:

�� Be via a licensed waste collector

�� To a licensed disposal facility, such as Chemical Waste Treatment

Centre

Spillage:

��

Contact immediately

the Contracts Manager and/or Foreman and report the spillage

��

Establish source of

spill or discharge and determine nature of material

��

Where possible halt

discharge

��

Commencing at the

source of the spill, establish all current and potential impacted areas

following the flow/drainage/infiltration paths to limit of spill and project

future path

��

Establish priority

order for containment of spill based on assessment above

��

Commence containment

of spill using bunds made from available materials and ground water cut-off

trenches where necessary

��

After spill is

contained remove material (including contaminated soil where necessary) using

pumps and/or absorbent materials

��

Dispose of the materials, including the

contaminated soil as chemical waste

The presence of a construction site with large

numbers of workers and site offices should result in general refuse requiring

disposal. This should mainly consist of food waste, aluminium cans and waste

paper.

��

Temporary storage

areas should be identify and provided for the temporary storage of general

refuse to facilitate collection

��

General refuse

generated on-site should be stored in enclosed bins or compaction units

separate from construction and chemical wastes

��

Temporary storage

areas for general refuse should be enclosed to avoid environmental

impacts. Sufficient dustbins should

be provided for storage of waste as required under the Public Cleansing and

Prevention of Nuisances Ordinance (Regional Council) By-laws

��

General refuse

should be cleared daily and should be disposed of to the nearest licensed

landfill or refuse transfer station

��

Separate labelled

bins should be provided to segregate the waste generated by workforce. Waste

recycle collector should be employed to collect the segregated waste

��

Cardboard and paper

packaging (for plant, equipment and materials) should be recovered on site,

properly stockpiled in dry condition and covered to prevent cross contamination

by other C&D materials

��

Office waste should

be minimized through using papers on both sides. Communication by electronic

means should be used as far as possible

��

Open burning of

refuse on-site is prohibited by law and should not be undertaken

��

Toilet wastewater

should be transported by a licensed contractor to a Government Sewage Treatment

Works for disposal in accordance with the Sanitation and Conservancy (Regional

Council) By-laws

��

In temporary stage, sewer from toilet and domestic wastewater from other

source like hand and cup washing should be discharged into holding tank and collect by license

collector. Application of ��Discharging Waste

Water into Existing Sewage Manhole�� was submitted to DSD for approval.

In permanent stage,

sewer and domestic wastewater will be discharged to existing sewer,

subject to DSD approval. Estimated volume of sewage flow was shown in Table

4.1.

��

Wastewater from the

chemical toilet should be emptied by licensed collector regularly.

To maintain the site in a clean and tidy

condition during the construction, the following general measures should be

implemented on site at all times. Regular site inspections should be undertaken

by the site team to ensure that the following general measures are observed on

site:

Daily cleaning

should be performed daily after work within the site and the public areas

immediately next to the site. It covers:

��

Clear passageways, common accesses and public areas, keep them free

from obstruction

��

All access routes, including public access, staff access, loading/

unloading access of vehicles, emergency access and emergency vehicular access

should be kept tidy, safe and convenient

��

Storing and stacking materials properly. Clearing stockpile and wastes

��

Sorting, storage and/or disposal of waste materials in accordance with

the WMP

��

Securing hoarding, barriers, guarding, lighting, and signing of works

properly

��

Removal and prevention of any water ponds and

flooding

Weekly tidying should be performed weekly within the site as well as

the public areas immediately next to the site. It covers:

��

Thorough cleaning of passageways, common accesses and public areas

��

Re-organize storage of materials for better utilization of storage

spaces and safe stacking

��

Maintenance, re-conditioning and cleaning of plants, tools and

equipment

��

Collect and remove waste off site in accordance with the Waste

Management Plan

��

Clean, re-condition and/or replace the hoarding, barriers, guarding,

lighting and signage of works to good working condition

��

Clear drains and channels to prevent flooding

To control the rodent problem, the Site shall

be maintained in a tidy state at all times to discourage rodent harbourage and detect rodents at an early stage. Refuse and

food must be kept in containers with well-fitted covers/rodent proof store

rooms to deprive rodents of food. The Contractor shall not attempt to disinfect

rodents by themselves but shall appoint a pest control services contractor for

rodent control services or contact district pest control offices or the Pest

Control Advisory Section of the Food and Environmental Hygiene Department for

rodent control advice.

In order to enhance the awareness of the workers

including those of the sub-contractors�� on waste management on site,

site-specific induction training and regular toolbox talks topic related but

not limited to site cleanliness and appropriate waste management procedures

including waste reduction, reuse and recycling should be provided to all site

staff.

Environmental Officer should identify the need

and arrange relative trainings for all employee and the sub-contractors��

workers involved in the works.

The training should cover the waste management

policy, targets, measures for on-site sorting of C&D materials and

measurement on waste management performance on the site.

An auditable record should be maintained for all

environmental training undertaken.

Site environmental inspection should be conducted in a monthly basis.

The Environmental Officer or Site Administrator and the Engineer or his

delegate should attend the inspection, in order to evaluate the overall performance of the implementation of

the WMP and ensure the appropriate control measures are properly implemented. The inspection

should also cover waste sorting, storage and disposal.

The aims and objectives of waste management

inspection are:

�� To ensure that the waste arising from works are handled, stored,

collected, transported and disposed of in an environmentally acceptable manner;

�� To ensure that the handling, storage, collection and disposal of waste arising

from the works comply with the relevant requirements under the Waste Disposal

Ordinance and its regulations;

�� To encourage the reuse and recycling of materials.

Project team should

take immediate action to rectify the deficiencies identified from the

inspection and report the status of rectification actions in the Monthly

Environmental Report.

Table 11.1 - Event Action Plan

for Non-compliance

|

Step

|

Day

|

Action

|

Contractor

|

ER

|

|

1

|

1

|

Create a new non-compliance record within 1 working day after making

an observation during a site audit. The project team should send a Notice of

Non-Compliance (NNC) to the ER. The NNC should include the observations and

the reasons for non-compliance.

|

*

|

|

|

2

|

2

|

Propose

corrective actions within 1 working day after the issue of the NNC.

|

*

|

+

|

|

3

|

2

|

Review and

agree the proposed corrective actions and make additional recommendations as

required.

|

|

*

+

|

|

4

|

2

|

Implement the

proposed corrective actions once they have been agreed.

|

*

|

|

|

5

|

-

|

Check the

implementation of the corrective actions at the next site audit. Close the

non-compliance record if the implementation of the corrective actions is

satisfactory.

|

*

+

|

|

|

6

|

-

|

Propose

preventive actions within 3 working days after the closure of the

non-compliance record.

|

*

|

+

|

Note:

* Action

party

+ Comments

on the non-compliance record where applicable

ER Engineer��s

Representative

The EO shall check whether GCL

has followed the relevant contract specifications and the procedures specified

under the laws of Hong Kong. In addition to the site inspections, the ET shall

review the documentation procedures prepared by the GCL once a week to ensure

proper records are being maintained and procedures undertaken in accordance

with the Waste Management Plan. The checklist is given in below Table 11.2:

Table 11.2 �V Waste Management

Checklist

|

Activities

|

Timing

|

Monitoring Frequency

|

If non-compliance, Action Required

|

|

All necessary waste disposal permits

or licenses have been obtained

|

Before the commencement of demolition works

|

Once

|

Apply for the necessary permits/licences prior to disposal of the waste. The ET

shall ensure that corrective action has been taken.

|

|

Only licensed waste haulier are used for waste collection.

|

Throughout the works

|

Weekly

|

Inform the ER of the noncompliance. The ER shall

instruct the Contractor to use a licensed waste haulier.

The Contractor shall temporarily suspend waste collection of that particular

waste until a licensed waste haulier is used. Corrective action shall be undertaken

within 48 hours.

|

|

Records of quantities of wastes generated,

recycled and disposed are properly kept. For demolition material/waste, the

number of loads for each day shall be recorded (quantity of waste can then be

estimated based on average truck load. Should landfill charging be

implemented, the receipts of the charge could be used for estimating the quantity).

|

Throughout the works

|

Weekly

|

The Contractor shall estimate the missing data

based on previous records and the activities carried out. The ET shall audit

the results and forward to the ER and IEC for approval.

|

|

Wastes are removed from site in a timely

manner. General refuse is collected on a daily basis.

|

Throughout the works

|

Weekly

|

Inform the ER of the noncompliance. The ER shall

instruct the Contractor to remove waste accordingly.

|

|

Waste storage areas are properly cleaned

and do not cause windblown litter and dust nuisance.

|

Throughout the works

|

Weekly

|

Inform the ER of the noncompliance. The ER shall

instruct the Contractor to clean the storage area and/or cover the waste.

|

|

Different types of waste are segregated

in different containers or skip to enhance recycling of material and proper

disposal of waste.

|

Throughout the works

|

Weekly

|

Inform the ER of the noncompliance. The ER shall

instruct the Contractor to provide separate skips/ containers. The Contractor

shall ensure the workers place the waste in the appropriate containers.

|

|

Chemical wastes are stored, handled

and disposed of in accordance with the Code of Practice on the Packaging,

Handling and Storage of Chemical Wastes, published by the EPD.

|

Throughout the works

|

Weekly

|

Inform the ER of the noncompliance. The ER shall

instruct the Contractor to rectify the problems immediately. Warning shall be

given to the Contractor if corrective actions are not taken within 24 hrs and the Waste Control Group of the EPD shall be

identified.

|

|

Demolition material/waste in dump

trucks are properly covered before leaving

the site.

|

Throughout the works

|

Weekly

|

Inform the ER of the noncompliance. The ER shall

instruct the Contractor to comply. The Contractor shall prevent trucks shall

leaving the site until the waste are properly covered.

|

|

Wastes are disposal of at licensed

sites.

|

Throughout the works

|

Weekly

|

Inform the ER of the noncompliance. The ER shall warn

the Contractor and instruct the Contractor to ensure the wastes are disposed

of at the licensed sites. Should it involve chemical waste, the Waste Control

Group of EPD shall be notified.

|

�� To facilitate monitoring and control over the site performance on waste

management, the following items should be discussed at internal meeting, such

as SSEC and SSEMC meeting, or other established channels for performance

monitoring:

�� Review the WMP including the quantities and types of C&D materials

generated, reused and disposed of off-site; the amount of fill materials

exported from/imported to the site and quantity of timber used in temporary

works construction, sample as presented in Appendix

C for each

process/ activity.

�� Review the implementation of the Construction Waste Disposal Charging

Scheme, and identify areas for improvement

�� Monitoring the achievement of the WMP to assess its effectiveness

�� Discuss and review on the results of the regular Waste Management

Inspection

�� Review the records on the inspection checklist of the Daily Cleaning

and Weekly Tidying

�� Review incidents of non-compliance and discuss the necessary follow-up

action identified

�� Monitor the follow-up action on defects and deficiencies identified

�� Contracts Manager should ensure the

implementation of Construction Waste Disposal Charging Scheme for recording the

C&D materials being removed off site. The site procedures for

implementation are as follows:

��

Contracts Manager should, within 21 days

after being awarded the contract, make an application for a billing account

solely in respect of that contract, using the form ��EPD-211 Form 1 -

Application for a Billing Account (Construction Work Contract with Value of $1

million or Above)��

��

Project Manager should assign competent personnel for the arrangement

for disposal of construction wastes

��

Before the construction wastes being removed off site, the dump truck

drivers should inform the delegated personnel for the ��Chit��

��

The delegated personnel should fill in a ��Chit�� for that particular

dump truck, issue the Part B & C of ��Chit�� to the dump truck driver and

retain Part A of the ��Chit�� for record

��

The dump truck driver should present Part B & C of ��Chit�� to

operator of designated waste disposal facilities, including the public filling

facility, public sorting facility and landfill, when using the disposal service

��

If the materials accords with the acceptance

criteria, the facilities operator should give Part B of ��Chit�� and a transaction receipt to the truck driver

after completion of the disposal

��

The truck drivers should give Part B of

��Chit�� and the transaction receipt back to the delegated

personnel for record

��

The delegated personnel should properly record all construction wastes being removed off site and check all

relevant records to ensure no illegal dumping

��

The delegated personnel should update

the status of ��Chits��. Enough number of chits should be available for disposal of construction

waste. If additional ��Chits�� required, the delegated personnel should fill in

the form ��EPD-214 Application for Issuance of Chits for Disposal of

Construction Waste for Existing Account-holder�� and submit it to EPD

��

If the ��Chits�� have been lost/ stolen, Project Manager should report to EPD in writing immediately

��

A monthly notice of demand and construction waste transaction

information of the specific project should be received from EPD. Project Manager should pay the specified prescribed charge within 45 days from the

date of the notice and in the manner specified in the notice

��

Contracts

Manager should regularly review the

monthly notice and counter-check with all relevant disposal records to ensure

that the billing account is solely used for payment any prescribed charge

payable in respect of construction waste generated from his/ her project

��

Training on the site procedures for implementation of charging scheme

should be provided to all site staff, including the supervisory staff, all

truck drivers and those employed by subcontractors.

��

All truck drivers must bear a valid Dumping License.

A Filing System should be developed for the

easy filing and effective retrieval of quality records. The environmental

related records should be filed and indexed as per the filing system that

should permit easy identification and access on a frequent basis.

All records, such as permits, site

inspection checklists & reports, etc., relating to the implementation of

the WMP, should be kept adequately and be properly recorded. The records should include, but not limited,

to the followings:

��

Environmental Permit

��

Training Records

��

Inspection Checklists and Records

��

Records of Trip-tickets system

��

Any other related records