1.1.1

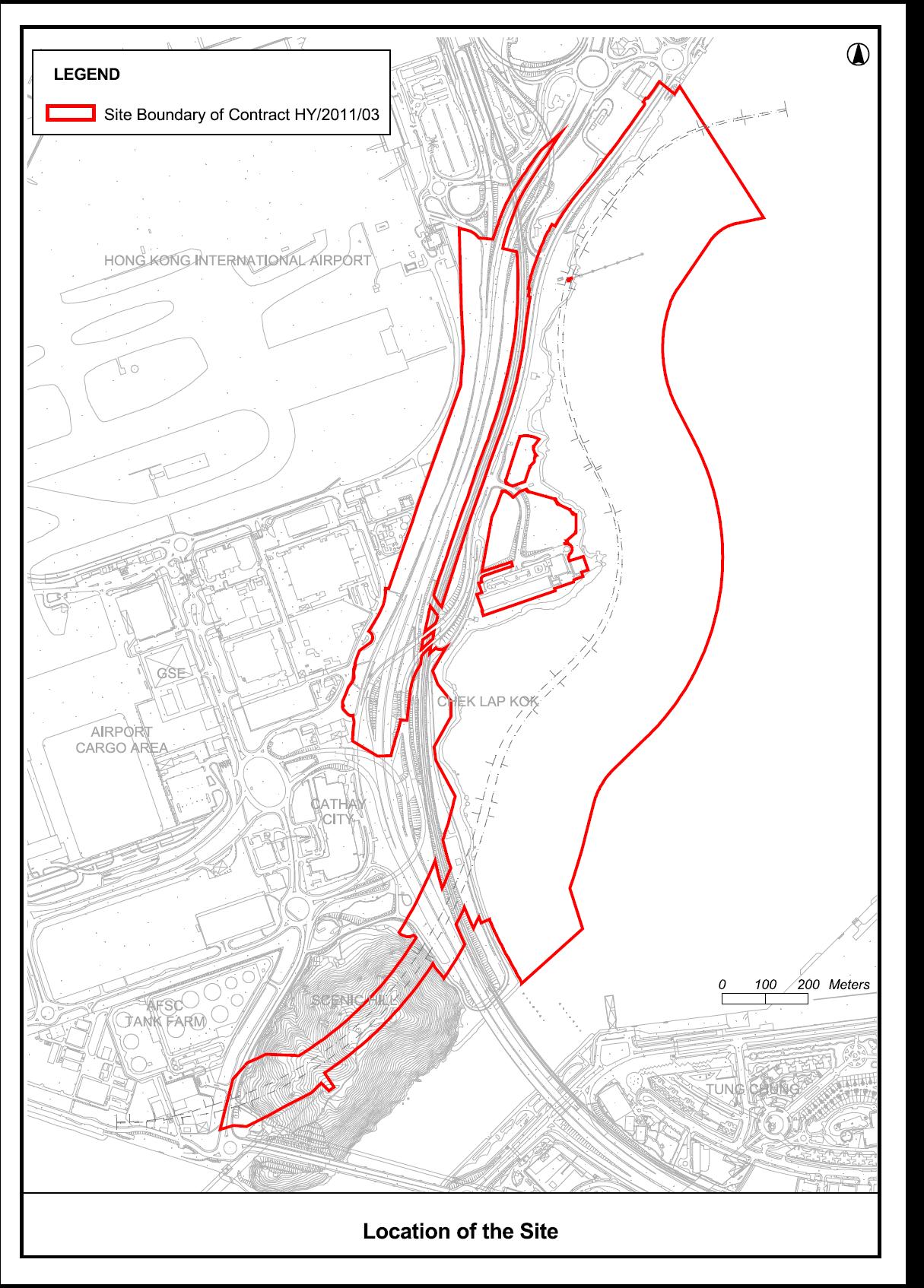

This Spill Response Plan (ˇ§SRPˇ¨) is prepared for

Contract HY/2011/03 Hong Kong-Zhuhai-Macao Bridge

Hong Kong Link Road ˇV Section between Scenic Hill and Hong Kong Boundary

Facilities (ˇ§the Contractˇ¨) for the Highways Department of HKSAR and the

General Site Area is presented as Appendix

A. The Contract is part of the

Hong Kong ˇV Zhuhai ˇV Macao Bridge Hong Kong Link Road

(HKLR) Project and Hong Kong ˇV Zhuhai ˇV Macao Bridge

Hong Kong Boundary Crossing Facilities (HKBCF) Project, these projects are

considered to be ˇ§Designated Projectsˇ¨, under Schedule 2 of the Environmental

Impact Assessment (EIA) Ordinance (Cap 499) and Environmental Impact Assessment

(EIA) Reports were prepared for the Project (Register No. AEIAR-144/2009

and AEIAR-145/2009). The

current Environmental Permit (EP) EP-352/2009/A for HKLR and EP-353/2009/D for

HKBCF were issued on 31 October 2011 and 7 March 2012, respectively. These

documents are available through the Environmental Impact Assessment Ordinance

Register.

1.1.2

The following Spill Response Plan is required

under and Clause 2.8 of EP No. EP-352/2009/A and Clause 2.7

of EP No. EP-353/2009/D, ˇ§The

Permit Holder shall deposit with the Director, at least one month before the

commencement of construction of the Project, three hard copies and one

electronic copy of a Spill Response Plan detailing the actions to be taken in

the event of accidental spillage of oil or other hazardous chemicals from

construction activities including vessels operating for the Project, with

specific provisions for protecting marine ecology and the Chinese White

Dolphins.ˇ¨

2.1.1

In order to minimize the potential for the

accidental release of fuel, oils, or other hazardous chemicals during the

construction of this contract, the following measures, subject to site

constraints, will be implemented for work areas and storage rooms/areas:

2.2.1

Drip trays will be used to collect any leakage

from operating equipment onsite such as generators. The drip trays will be regularly emptied

and maintained by the onsite workforce and the contents of the drip trays will

be stored in suitable containers for subsequent transportation and disposal at

a licensed chemical waste collector or treatment facilities.

2.2.2

Operators of equipment (such as excavators,

trucks etc.) will inspect the equipment that they are using on a regular basis

for leaks or drips. Should any

leaks or drips be identified they must be repaired prior to the equipment being

used.

2.2.3

Vehicle maintenance will be carried out on a

regular basis and upon necessary during the course of the contract and good

housekeeping practices will be implemented.

2.2.4

A product inventory will be maintained with

details (chemical details, number of storage containers, location etc.) of all

containers of chemicals, chemical waste that is stored onsite.

2.2.5

Any oil filling activities should be carried out

within a bunded area or inside a drip tray to

minimize the potential for spillages.

2.3.1

Drip trays will be used to collect any leakage

from operating equipment used on vessels and works at sea, such as

generators. The drip trays will be

regularly emptied and maintained by the crew/workforce and the contents of the

drip trays will be stored in suitable containers for subsequent transportation

and disposal at a licensed chemical waste collector or treatment facilities.

2.3.2

Operators of equipment will inspect the

equipment that they are using on a regular basis for leaks or drips. Should any leaks or drips be identified

they must be repaired prior to the equipment being used.

2.3.3

Maintenance of vessels will be carried out on a

regular basis and upon necessary during the course of the contract and good

housekeeping practices will be implemented.

2.3.4

Any oil filling activities should be carried out

within a bunded area or inside a drip tray to

minimize the potential for spillages.

2.4.1

Appropriate drums and other storage containers,

depend on the characteristics of chemicals, will be used for stored within a

storage area.

2.4.2

Drums and other storage containers used onsite,

will be tightly sealed at all times, when not in use, to minimize the release

of the drum or storage containerˇ¦s contents, to the environment if knocked

over.

2.4.3

Specific areas for the storage of drums and

other containers of similar or compatible contents will be identified and used

and will be located as far as practicable from the coast and bodies of

water. Incompatible chemicals will

be stored separately. The storage

areas will be adequately ventilated as necessary to prevent the buildup of a

hazardous environment.

Additionally, bunding or another suitable

containment system will be constructed for the storage areas to isolate any

spill or release that may take place.

2.4.4

Storage areas will be inspected on a weekly

basis, for signs of spills (such as staining on the ground), general

housekeeping, availability of appropriate spill control supplies and also to

confirm that the drums and/or storage containers are in good condition (e.g.

not holed or rusted), are properly stored and are appropriately sealed.

2.4.5

Suitable storage containers which are resistant

to the stored chemical will be used for the storage of chemicals and fuel onsite.

2.4.6

All drums and other storage containers used to

store hazardous chemicals onsite will be clearly labeled.

2.4.7

Smoking and the use of open flames will be

prohibited near the chemical storage areas and signage will be posted informing

the workforce of this requirement.

2.4.8

Adequate space will be provided in the storage

areas for the safe and easy handling, and inspection of the storage containers.

2.4.9

The point of ingress to the chemical storage

area will be locked.

2.4.10 Suitable

firefighting (i.e. extinguishers suitable for the chemicals being stored),

spill response (e.g. absorbent pads) and health and safety equipment will be

located in, or, in the vicinity of the storage areas. Suitable signage will also be posted

with the appropriate emergency contact information and evacuation routes and

also to highlight the location of equipment to the workforce and any emergency

responders.

2.4.11 The

chemical storage area will be used for chemical storage only and will be

enclosed on three sides with materials suitable for the construction of such

enclosures.

2.4.12 The

storage area will have an impermeable floor or surface made of suitable

materials for the storage of containers of chemicals. The storage area will be designed to

contain the contents of the largest container intended for use or 20% of the

total quantity of the chemicals to be stored, whichever is greater.

2.5.1

Appropriate drums and other storage containers,

depend on the characteristics of chemical wastes, will be used to store

chemical waste.

2.5.2

Drums and other chemical waste storage

containers used onsite, will be tightly sealed at all times, when not in use,

to minimize the release of the drum or storage containerˇ¦s contents, to the

environment if knocked over.

2.5.3

Specific areas for the storage of chemical waste

will be identified and used and will be located as far as practicable from the

coast and bodies of water

2.5.4

Chemical waste storage areas will be inspected

on a weekly basis, concurrent with the inspection of chemical storage areas,

for signs of spills (such as staining on the ground), general housekeeping,

availability of appropriate spill control supplies and also to confirm that the

drums and/or chemical waste storage containers are in good condition (e.g. not

holed or rusted), are properly stored and are appropriately sealed.

2.5.5

Suitable storage containers which are resistant

to the stored chemical waste will be used for the storage of chemical waste

products onsite.

2.5.6

All drums and other storage containers used to

store chemical waste onsite will be clearly labeled in accordance with the Code

of Practice on the Packaging, Labelling and Storage

of Chemical Wastes.

2.5.7

Smoking and the use of open flames will be

prohibited near the chemical waste storage and signage will be posted informing

the workforce of this requirement.

2.5.8

Adequate space will be provided in the chemical

waste storage area for the safe and easy handling, and inspection of the

storage containers.

2.5.9

The point of ingress to the chemical waste

storage area will be locked.

2.5.10 Suitable

firefighting (i.e. extinguishers suitable for the chemicals being stored),

spill response (e.g. absorbent pads) and health and safety equipment will be

located in, or, in the vicinity of the chemical waste storage area. Suitable signage will also be posted

with the appropriate emergency contact information and evacuation routes and

also to highlight the location of equipment to the workforce and any emergency

responders.

2.5.11 The

chemical waste storage areas, will be, where practicable, located close to the

source of the waste generation to minimize waste handling and to facilitate

management control.

2.5.12 The

chemical waste storage area will be used for chemical waste storage only and

will be enclosed on three sides with materials suitable for the construction of

such enclosures.

2.5.13 The

storage area will have an impermeable floor or surface made of suitable

materials for the storage of containers of liquid chemical waste. The storage area will be designed to

contain the contents of the largest container intended for use or 20% of the

total quantity of chemical waste to be stored, whichever is greater.

2.5.14 Should

there be less than 300L of chemical waste produced a cupboard or cabinet will

be used with shelves with a leak proof sill or spill catcher trays and

ventilation holes.

3.1.1

In order to minimize the risk of accidental

spills occurring during the transportation of drums or storage containers of

chemicals to and from the site, the following precautionary measures, subject

to site constraints, will be used:

i.

Suitably sized storage containers will be used

onsite to reduce the risk of spills due to overfilling.

ii.

Ensure that only appropriate, safe and suitably

labeled drums or other storage containers are used onsite.

iii. Onsite,

where possible, manual pumping systems will be used to transfer chemical waste

between storage containers, instead of manually pouring.

iv. Provide

bunding or another suitable containment structure will

be provided onsite to isolate any chemicals, chemical waste, fuel that is

spilled.

v.

Only use suitable equipment (forklift, trolley,

etc) to transport the chemicals, chemical waste onsite and to and from trucks.

vi. Only

engage suitably licensed, trained and responsible chemical waste collection

companies to carry out the transportation of chemicals, chemical waste to and

from the site.

vii. The

storage containers should be checked to ensure they are tightly sealed with no

leakage before loading on the trucks for transportation.

viii. Suitable

preventative measures (such as anchoring of containers, avoiding stacking

containers, etc) should be taken to avoid any spillage during transportation of

containers.

4.1.1

The response to any spill onsite shall be

carried out promptly and efficiently, to minimize the amount of oil or other

hazardous chemical or chemical waste that is released into the

environment. The general spill

response includes the following:

4.2.1

Suitable signage should be posted to inform

workers of emergency telephone numbers, the location/s of emergency shower

stations, the location of spill response and firefighting equipment, and

emergency evacuation routes.

4.2.2

Should a spill response be necessary, the

following steps will be followed:

i.

Immediately inform the Emergency Team of the

following details of the spill incident:

-

The approximate location of the

spill.

-

The type and approximate

quantity of material spilled.

-

Details of what the material

spilled onto, such as concrete or dirt.

-

The time of the spill.

-

Whether the spill is contained

(by bunding etc) or has reached the environment.

ii.

Take all reasonable measures to isolate,

contain, reduce and/or stop the spillage, provided it is safe to do so.

iii. Provided

it is safe to do so, the area containing the spill shall be ventilated by

mechanical means in order to make a safe spillage condition.

iv. The

Emergency Team Leader shall be responsible for organizing adequate resources to

identify the spill source and if necessary stop or cease it.

v.

The Emergency Team Leader as the assigned person

shall equip all people involved in the cleanup works with suitable personal

protective equipment (ˇ§PPEˇ¨) prior to the removal of any leaked chemical,

chemical waste.

vi. Suitable

spill response equipment such as absorbent pads, dry sand or sawdust shall be

used to absorb the leakage. Any

contaminated spill response equipment shall be collected after cleaning up the

spill and sealed in black plastic bags and clearly labeled as "chemical

waste". All collected chemical

waste shall be placed in an area designated for chemical waste storage and

transported by an approved company to an approved disposal facility.

vii. An

incident report will be submitted to the Supervising Officerˇ¦s Representative

(SOR) within two working days of the spill.

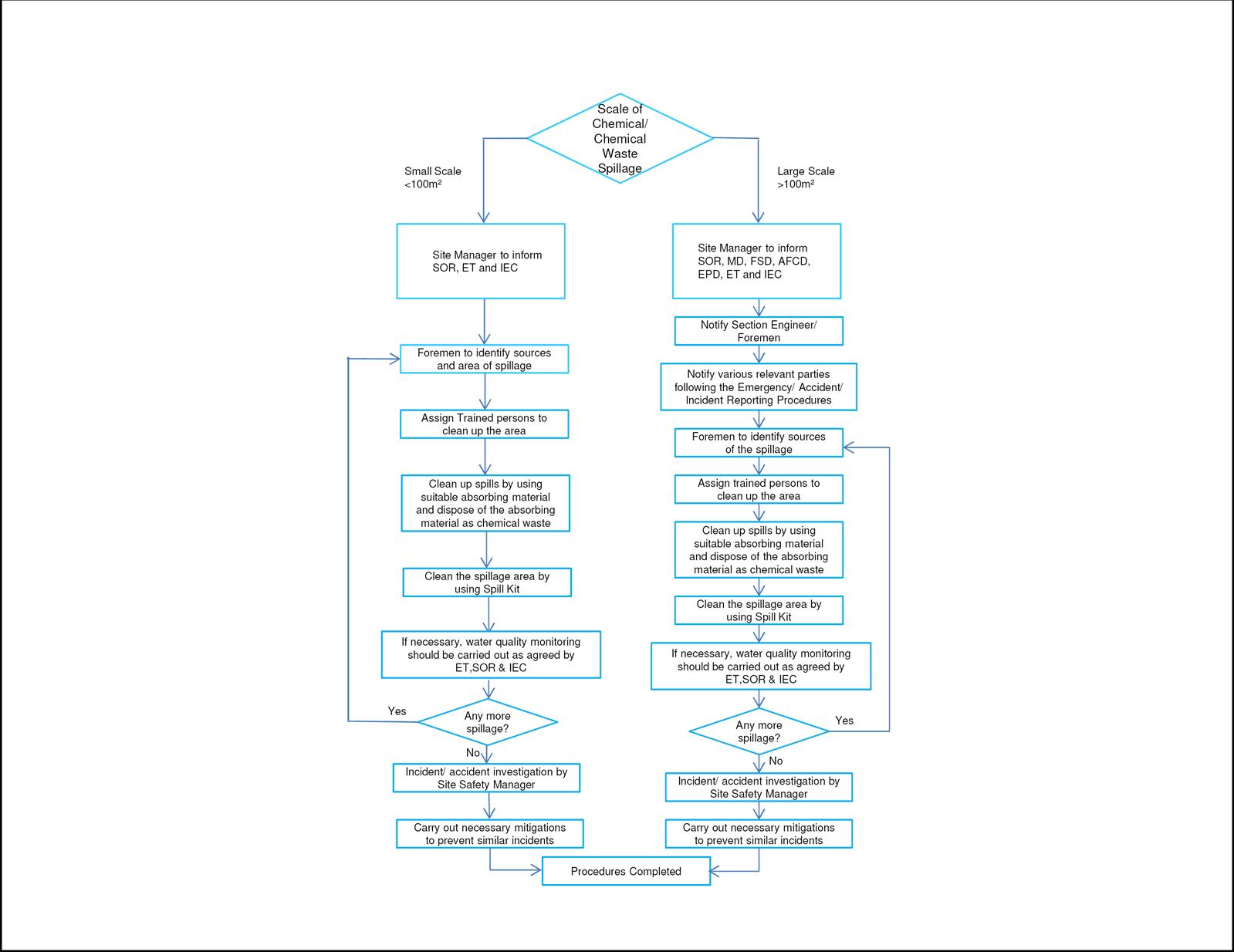

4.3

Spill into the Marine Environment

4.3.1

A spill into the marine environment is

considered to be serious, given the vulnerability of the marine ecosystem to

chemicals. This notification system

is separated into two scales, depending upon the approximate area affected by

the spill.

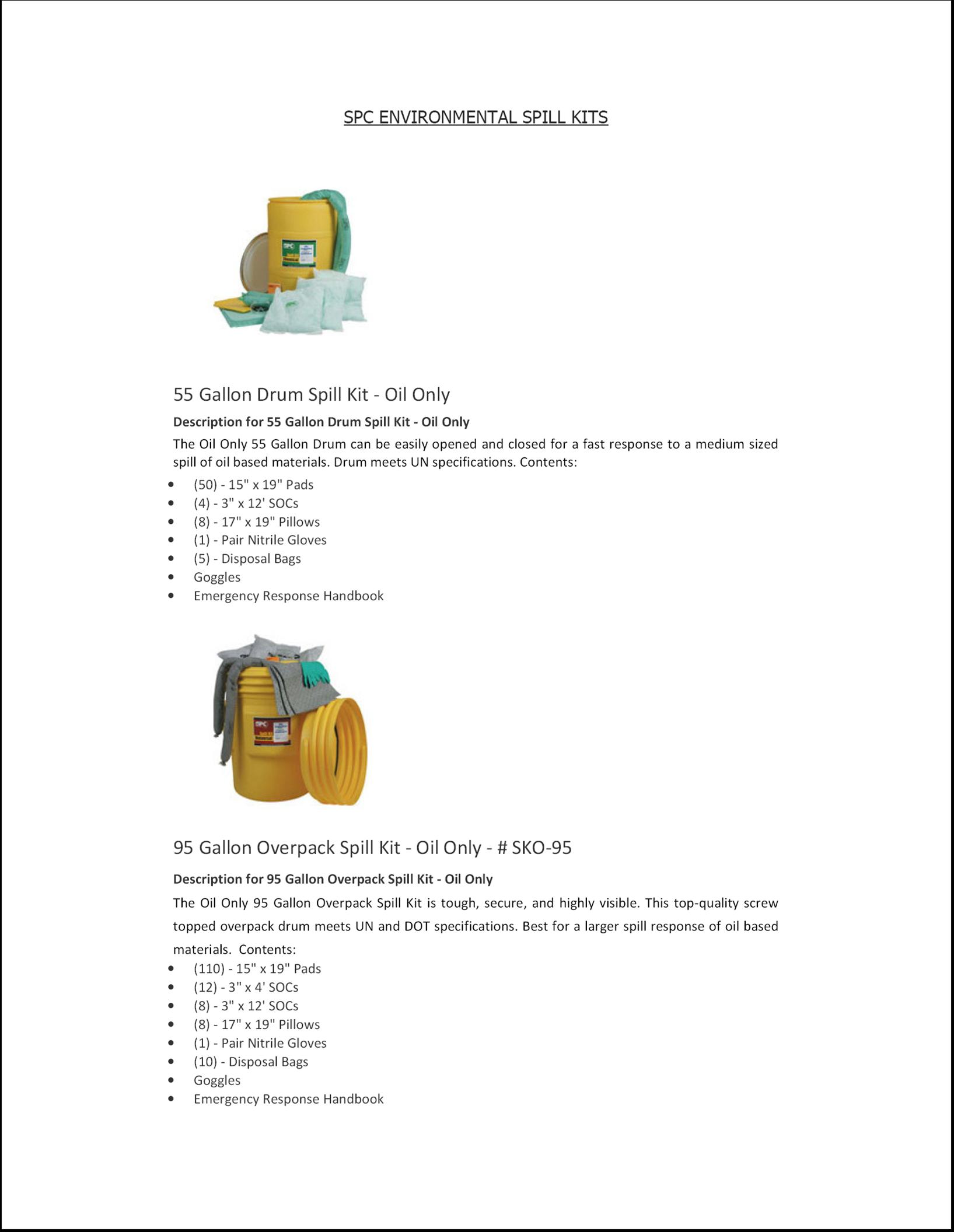

4.3.2

Immediately upon identifying a spill, CSHK will

use suitable spill response equipment (such as spill kits, booms, oil

dispersant, etc) to contain the spill.

The standard spill kit includes items such as absorbent pads and pillows

and Secondary Oil Containment.

Secondary Oil Containment is used to enclose the spill area and to

prevent the spill from migrating outside of the Secondary Oil Containment. The absorbent pads and pillow are used

for absorbing and recovering the spill that is contained within the Secondary

Oil Containment. Examples of

standard spill kit equipment are provided in Appendix C of this SRP.

4.3.3

It is the responsibility of the person observing

the spill to report details of their observation immediately to their

supervisor, who shall inform the Foremen and Site Manager as Emergency Team

Leader. The Foremen shall be

assigned to deploy the spill kits to the spill site. Depending on the scale of the spillage

area, the reporting system is separated into the following two systems:

i.

For a spill area of greater than 100 m2:

-

The Site Manager shall inform

all parties such as the SOR, Marine Department (MD), Fire Services Department,

Agriculture, Fisheries and Conservation Department (AFCD), Environmental

Protection Department (EPD), Environmental Team (ET) and Independent

Environmental Checker (IEC) immediately.

The parties to be contacted are listed in Section 8.0 of this SRP.

-

The weather forecast for the

area will also be used to determine the likely direction of movement (if any)

of the surface spill

-

The Emergency Team Leader shall

be responsible for organizing adequate resources to identify the spill source

and if necessary stop or cease it.

-

The Emergency Team Leader as the

assigned person shall equip all people involved in the cleanup works with

suitable PPE prior to the removal of any leaked chemical, chemical waste.

-

The spillage area shall be

contained using the Secondary Oil Containment of the spill kit.

-

Booms together with the

absorbent pads and pillows of the spill kit shall be deployed to contain,

absorb and mitigate the spillage within the Secondary Oil Containment. The absorbent pads and pillows will be

collected into disposal bags that are part of the spill kit.

-

An incident report will be

submitted to the SOR within two working days of the spill

ii.

For a spill area less than 100 m2:

-

The Site Manager shall inform

the parties such as the SOR, ET and IEC immediately. The parties to be contacted are listed

in Section 8.0 of this SRP.

-

The Emergency Team Leader shall

be responsible for organizing adequate resources to identify the spill source

and if necessary stop or cease it.

-

The Emergency Team Leader as the

assigned person shall equip all people involved in the cleanup works with

suitable PPE prior to the removal of any leaked chemical, chemical waste.

-

The spillage area shall be

contained by using the Secondary Oil Containment of the spill kit.

-

Absorbent pads and pillows of

the spill kit shall be deployed to absorb and mitigate the spillage within the

Secondary Oil Containment. The

absorbent pads and pillows will be collected into disposal bags that are part of

the spill kit.

-

An incident report will be submitted

to the SOR within two working days of the spill.

4.4.1

A spill of during the construction of the tunnel

portion of the contract is also considered to be serious, given the restricted

access to the tunnel, an enclosed atmosphere that will be regulated by

mechanical ventilation and general tight working conditions. Signage will be posted to inform workers

of emergency telephone numbers, the location/s of emergency shower stations,

the location of spill response and firefighting equipment, and emergency

evacuation routes. In addition to

signage, suitable means of communication will be needed by workers in case of a

spill.

4.4.2

Should a spill take place underground during

construction of the tunnel, the following steps should be taken:

i.

Immediately inform the Emergency Team of the

following details of the spill incident:

-

The approximate location of the

spill.

-

The type and approximate

quantity of material spilled.

-

Details of what the material

spilled onto, such as concrete or dirt.

-

The time of the spill.

-

Whether the spill is contained

(by bunding etc.) or has reached the environment.

ii.

Take all reasonable measures to isolate,

contain, reduce and/or stop the spillage, provided it is safe to do so.

iii. Given

that the spill will be in a tunnel, provided that it is safe to do so,

mechanical ventilation should be maintained to prevent the buildup of a toxic

and/or explosive atmosphere.

iv. The

Emergency Team Leader shall be responsible for organizing adequate resources to

identify the spill source and if necessary stop or cease it.

v.

The Emergency Team Leader as the assigned person

shall equip all people involved in the cleanup works with suitable PPE prior to

the removal of any leaked chemical, chemical waste.

vi. The

Emergency Team Leader or a designated representative will monitor the

atmosphere during the cleanup of the spill and if a hazardous atmosphere is

identified evacuate workers from the spill area and continue to ventilate the

spill area

vii. Suitable

spill response equipment such as absorbent pads, dry sand or sawdust shall be

used to absorb the leakage. Any

contaminated spill response equipment shall be collected after cleaning up the

spill and sealed in black plastic bags and clearly labeled as "chemical

waste". All collected chemical

waste shall be placed in an area designated for chemical waste storage and

transported by an approved company to an approved disposal facility

viii.

An incident report will be submitted to the SOR

within two working days of the spill.

4.5.1

One spill kit will be distributed around the

site at locations nearby to any storage area

for chemicals /chemical waste.

Additional spill kits will also be located near to the office of the

Environmental Officer and the Environmental Officer shall ensure that

sufficient spill kits available on site at all times.

4.5.2

Absorbent pads and pillows of the spill kits

mitigate spills by means of physical absorption. No chemical or biological reaction would

take place during whilst using the absorbent pads and pillows. Used absorbent pads and pillows will be

collected after completion of spillage removal.

4.5.3

The inventory of hazardous chemicals that will

be used for this contract will be inspected periodically by the Environmental

Officer and Foremen every two months.

4.5.4

At least four sets of spill kits will be

provided on site in case of any emergency and the inventory of spill kits will

be managed by the on shift Foremen or Emergency Team Leaderˇ¦s delegates

(numbers and locations of the spill kits will be discussed in Section 7.2). CSHK will also provide additional spill

kit(s) on site when it is deemed necessary, and the total numbers of such kits

would be agreed with the SOR.

4.6.1

It is anticipated that the major chemical that

will be stored onsite during the construction of the contract will be

lubricants and oils are also anticipated to be stored onsite for the

maintenance of equipment.

4.6.2

An inventory of the hazardous chemicals that are

stored onsite will be maintained and regularly updated by the contractor. This inventory will contain details of

the type of chemicals, the quantity of chemicals, the storage container (e.g.

steel drum) and the location of material onsite. All subcontractors present onsite will

provide details of the chemicals that they are storing onsite. Checks of the materials that are stored

onsite by subcontractors will be made by Foreman from CSHK, together with

Foremen from the subcontractors.

The inventory and check record will be made available for inspection by

the SOR.

4.7.1

The information that is outlined within this

section will become applicable if the area of a spill is estimated to be

greater than 100m2. In

order to protect sensitive receviers within the

vicinity of the HKLR site during a spill of greater than 100m2 the

following steps will be taken:

i.

The location of the spill relative to a sensitive water receivers such as water intakes,

ecological sensitive receivers and Tai Ho Wan will be determined.

ii.

Absorbent booms, or similar, will be deployed

near to the receptors to protect sensitive marine receptors.

iii. The

Contractor will immediately inform the relevant parties as outlined in Section

4.2 of this SRP.

iv. The

on shift Foremen or Emergency Team Leaderˇ¦s delegates will employ all possible

mitigation measures in order to isolate the spill and minimize any potential

adverse effects to sensitive marine receptors.

v.

Follow the procedures that are outlined in Appendix B of this SRP.

vi. The

Contractor, SOR,

ET and IEC will discuss and implement a suitable program of water sampling to

monitor for any potential adverse effects to sensitive receptors.

5.1.1

It is not known what specific impacts a spill of

diesel fuel, or other chemicals would have upon the Chinese White Dolphin and

its food supply. Given that these

effects are unclear, a proactive approach will be used to isolate the Chinese

White Dolphins from any spill response event that may take place during the

course of the construction of the contract.

5.2.1

Observations from platform(s)

as high as practicable will be used to determine the approximate size of a

spill.

5.2.2

Whilst determining the size of the spill it will

be determined whether any Chinese White Dolphins are present in the vicinity of

the spill.

5.2.3

The weather forecast for the area will also be

used to determine the likely direction of movement (if any) of the surface

spill. In addition the vessel

traffic centre will be contacted to determine if any vessels may pass through

the location of the spill.

5.2.4

A suitable course of action can then be decided

upon once information such as the size of the spill, the proximity of any

Chinese White Dolphins to the spills and the likelihood of the Chinese White

Dolphins encountering the spill.

5.3.1

The use of absorbent booms is an effective

containment method for small spills within the marine environment and will

prevent the spread of a spill and thus help to minimize the potential for

Chinese White Dolphins to come into contact with the spill. Deployment of such absorbent booms,

together with teams of observers is considered to be an appropriate response to

a small spill that can be cleaned up in the short term.

5.3.2

In the event of spills of a larger area, the

deployment of underwater barrier nets (such as anti-shark nets) in addition to

the measures outline above, could be an effective means of isolating the spill

area from Chinese White Dolphins.

5.3.3

If Chinese White Dolphin(s) is/are observed

within the enclosed area which contains the spill, the same protocol used in

the event of injury or of live stranded cetaceans, as described in the Dolphin

Watch Plan will be followed.

6.1.1

The following is a list of the health and safety

equipment that will be made available on site:

i.

Fire extinguishers (such as foam) which are

suitable for fighting fires with flammable or combustible liquids.

ii.

Brushes, dustpans, mops and buckets.

iii. Dry

sand, sawdust or other absorbent material.

iv. Tissue

and towels (both paper and cloth).

v.

Storage containers or drums that will be

suitable for the storage of including plastic bags, absorbent pads, etc.

vi. Spill

response kits.

7.1.1

The onsite workforce will receive training from

the Environmental Officer regarding the measures outlined in this SRP, during

the site induction training, and the Environmental Officer shall periodically conduct

Tool Box talks with the site workers regarding the SRP. During the induction training, a

demonstration of the containment methods and equipment shall be carried out by

the Environmental Officer. All site

workers will be required to receive this training.

Table 7.1 Site

Training Requirements

|

Trainer

|

Training

|

Staff

|

Training Frequency

|

|

Environmental Officer

|

Safety around spills

|

All Workers

|

Every two months

|

|

Containment of spills

|

All Foremen

|

|

Recovery and clean up of spills

|

Every two months

|

|

Disposal of spill response waste

|

|

Reporting of spills

|

|

Types of sensitive receptors

|

Worker involved with handling

hazardous chemicals or fuel.

All Foremen

|

Every two months

|

|

Locations of the sensitive

receptors

|

|

Methods to protect these

sensitive receptors from spills and the necessary response to spills outlined

in this SRP

|

7.1.2

In the event of a spill being identified, the

spill response outlined in Section 4.0 of this SRP will be followed. For the contact information of the

relevant parties please refer to Section 8.0 of this SRP. CSHK will follow the procedures outlined

in Appendix B of this SRP.

7.2.1

One spill kit will be stored onsite near to

chemical storage areas. Three spill

kits will be on the vessels involved in the marine works ready for use if a

spill takes place. A further two

spill kits would be stored on patrol boat/s and any platforms used for dolphin

monitoring. The Environmental

Officer will notify Foremen of the locations of spill kits.

8

Relevant

Party Contact List

8.1.1

The following tables provide details of the

parties that maybe contacted during a spill.

Table 8.1 Emergency

Team Contact List

|

Role

|

Contact

Details

|

|

Site Manager

|

9633 0973

|

|

Deputy Site Agent

|

9078 0458

|

|

Construction Manager

|

9424 8437

|

|

9097 1310

|

|

9672 8904

|

|

9869 0631

|

|

Site Safety Manager

|

9424 2146

|

|

Traffic Coordinator

|

9484 1926

|

|

Environmental Officer

|

9842 2703

|

|

Environmental Supervisor

|

9255 9301

|

|

9220 1070

|

|

9308 0838

|

|

Foremen

|

9040 7725

|

|

9789 0772

|

|

9132 0177

|

|

9045 7022

|

Table 8.2 Government

Agency/Department Contact List

|

Agency /

Department

|

Contact

Details

|

|

General Emergency Services

|

999

|

|

Labour Department

|

2717 1717

|

|

Fire Services Department

|

2723 2233

|

|

Agriculture, Fisheries and Conservation Department

|

2708 8885

|

|

Environmental Protection Department

|

2838 3111

|

|

Nearest Fire Stations:

|

Tung Chung Fire Station

|

2988 1898

|

|

Chek Lap Kok Fire Station

|

2949 9081

|

|

Nearest Ambulance Depots:

|

Tung Chung Ambulance Depot

|

2988 8282

|

|

Castle Peak Bay Ambulance Depot

|

2451 7193

|

|

Nearest Hospital:

|

Tuen Mun Hospital

|

2468 5111

|

|

Hong Kong Airport Authority

|

2186 7111

|

|

Weather Forecast

|

187 8200

|

|

Marine Department

|

2852 4472-77

|

|

Vessel Traffic Centre

|

2858 2163 , VHF channel

12 or 14

|

|

Marine Police Control Centre

|

2803 6241

|

|

Maritime Rescue Coordination Centre

|

2545 0181 or 2233 7999

|

Table 8.3 Utility

Company Contact List

|

Utility Company

|

Contact

Details

|

|

China Light and Power Co. Ltd.

|

2728 8333

|

|

China Gas Co. Ltd.

|

2880 6999

|

|

Water Supplies Department

|

Hong Kong & Island

|

2811 0788

|

|

Kowloon & New Territory

|

2396 0210

|

Table 8.4 Supervising

Officerˇ¦s Representative Contact List

|

Title

|

Name

|

Contact

Details

|

|

CRE

|

Robert Evans

|

2528 3031

|

Table 8.5 Environmental

Team (BMT Asia Pacific) Contact List

|

Title

|

Name

|

Contact

Details

|

|

Environmental Team Leader

|

Claudine Lee

|

2815 2221

|

Table 8.6 Independent

Environmental Checker Contact List

|

Title

|

Name

|

Contact

Details

|

|

IEC

|

Antony Wong

|

3743 0788

|

9.1.1

The Site Manager is responsible for ensuring the

commitment onsite to the SRP and ensuring that adequate resources are available

to fulfill the requirements of the SRP.

9.1.2

The Site Manager will also fulfill the role of

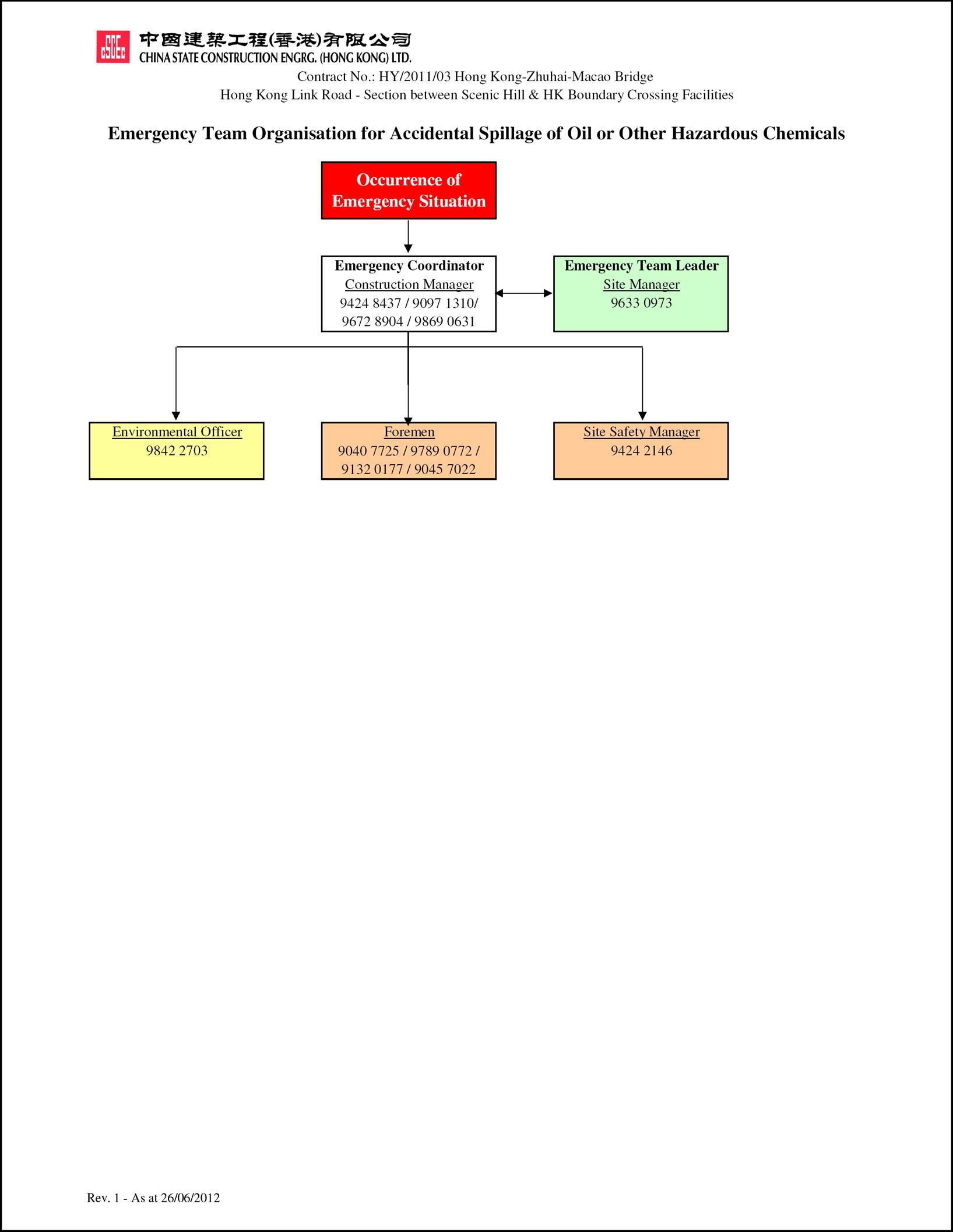

the Emergency Team Leader for spill response and will inform the Emergency Team

of the details of any spills as outlined in this SRP.

9.1.3

The Site Manager is also responsible to inform

relevant external parties in the event of spillage in accordance to Appendix B

of this SRP.

9.2.1

The Deputy Site Agent is responsible for

assisting the Site Manager in ensuring the commitment onsite to the SRP.

9.3.1

The Construction Manager reports to the Site

Manager and coordinates all environmental matters related to the SRP

onsite. The Construction Manager is

also responsible for all site operations, management of environmental issues,

staff supervision, control, coordination, planning, external liaison as well as

implementing and monitoring necessary corrective actions as they relate to the

SRP. With the assistance of the

Environmental Officer, he would also oversee the implementation and performance

of the SRP.

9.3.2

The Construction Manager will also act as an

Emergency Coordinator should a spill occur on the site and assist the Site

Manager as outlined in this SRP.

9.4.1

The Site Safety Manager is responsible for all

safety, health and environmental matters related to the SRP.

9.4.2

The Site Safety Manager is also assist in the investigation

of spill incidents and accidents as outlined in this SRP.

9.5.1

The Traffic Coordinator is responsible for

managing the onsite movements of vehicles transporting chemicals and other

hazardous chemicals in accordance with the SRP.

9.6.1

The Environmental Officer will be appointed on

site for the overall coordination, monitoring and overseeing the performance

and implementation of the SRP on the site.

The responsibilities of the Environmental Officer are as follows:

ˇP

Review the SRP, and ensure that all work onsite

is executed in accordance with the requirements of the SRP.

ˇP

Implement the measures and requirements outlined

in the SRP onsite.

ˇP

Train the workforce in the requirements of the

SRP as outlined in this SRP.

9.7.1

The Environmental Supervisor is responsible for

the implementation of the SRP with the assistance of the Foremen. The Environmental Supervisors are also

responsible for:

ˇP

Assisting the Environmental Officer in a spill

response as outlined in this SRP.

ˇP

Attend environmental meetings relating to this

SRP, when necessary.

ˇP

Carry out environmental site inspections with

the Environmental Officer as outlined in this SRP

9.8.1

The Foremen are responsible for site supervision

and coordination of the works as well as implementation of any spill response

actions required by this SRP, as directed by the Construction Manager /

Environmental Officer. The Foremen

are also responsible for:

ˇP

Assisting in the implementation of the SRP.

ˇP

Supervise the cleanup, as outlined in this SRP,

of any spills.

ˇP

Ensuring that waste generated during the cleanup

of any spills, is collected and stored appropriately as outlined in this SRP.

ˇP

Foremen shall be required to deploy spill kits

when a spill occurs as outlined in this SRP.

9.9.1

The workers are responsible to carry out the

requirements of this SRP and follow the instructions of Foremen as they relate

to this SRP. They are required to

carry out the following tasks:

ˇP

Attend training given by the Environmental

Officer in the correct handling and storage of chemicals on site as outlined in

this SRP.

ˇP

Use spill kits, when directed in accordance with

this SRP.

ˇP

Collect and store wastes generated during the

cleanup of any spills as outlined in this SRP.

10

Notification

to Relevant Parties

10.1.1 If

a spill is small and can be contained and cleaned up easily, then the

Environmental Officer shall be informed and information will be given to the

SOR in an incident report within two working days. The Environmental Officer or SOR may

choose to inspect the area if the spill is less than 100m2 to

confirm that the spill is contained and the correct / most suitable clean up

procedure has been implemented. For

all spills, photographs shall be taken (before and after) cleaning up to document

the cleanup of the spill.

10.1.2 The

Environmental Officer shall be responsible for maintaining a record of all

spills onsite and the record will be provided to the SOR upon request. For spills larger than 100m2,

the Environmental Officer and the SOR will attend the area to confirm that the

spill has been contained and cleanup methods, as outlined in this SRP were

used. A photographic record shall

be kept, as shall a record by both the Environmental Officer and the SOR. The Construction Manager and Site Safety

Manager shall also be informed of the incident. If the spill was contained and no

significant quantity entered into the marine environment, then the event shall

be documented in an incident report for submission to the SOR.

10.1.3 If

a significant release of fuel or other chemicals to the marine environment

occurs (spill of greater than 100m2), then a full scale notification

shall occur. Under such

circumstances, the people identified in the relevant parties section of this

SRP shall be notified for support as needed. The contact details of the relevant

parties are listed in Section 8.0 of this SRP.

11

Emergency

Team Organization

11.1.1 The

SRP Emergency Team Organization Chart is shown in Appendix D.

![]()

![]()